As we all known, the exhaust catback plays a very important role in the car. On the one hand, it can not only purify harmful substances in the exhaust, ensure the healthy and efficient operation of the engine, but also reduce the noise. At present, Jagrow exhaust catback are mainly made of 304 stainless steel and titanium alloy.

So how does Jagrow make a stainless steel exhaust catback that protects the engine and reduces noise, mainly divided into the following steps.

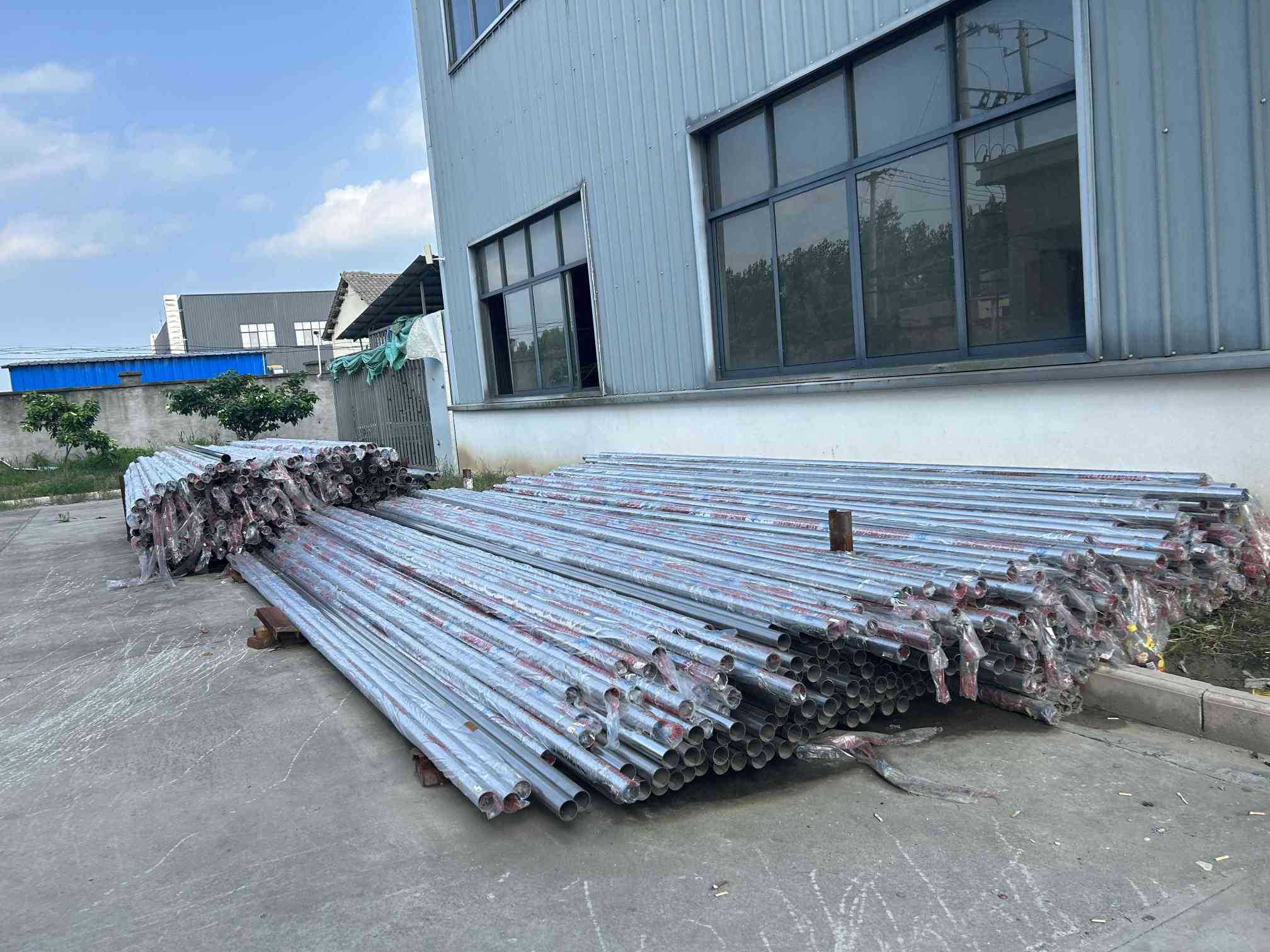

1.Cut the 304 stainless steel raw material and use the machine to cut it into the required length, which is convenient for production.

2. Use the pipe bending machine to adjust the data. The pipe bending machine is distinguished according to the diameter of the pipe. Different angles can be set on each machine. Put the stainless steel pipe into the pipe bender and bend it according to the data.

3. After the stainless steel pipe is bent into the required angle, it is surface treated, polished or brushed.

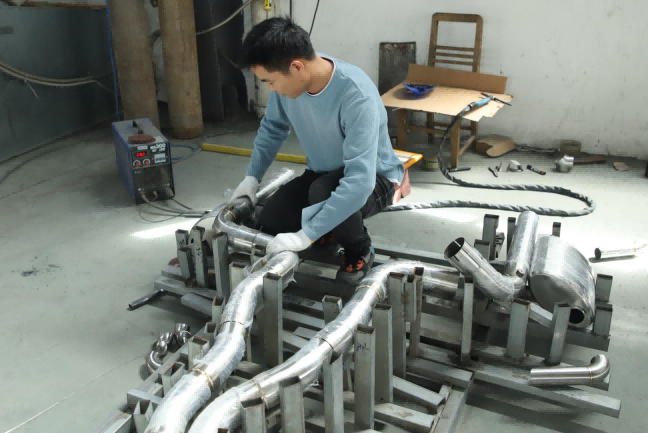

4. Put the processed pipe on the mold for assembly, and then weld it, first spot welding, then full welding.

5. After the pipe is welded, put the middle end section on the mold again for confirmation, quality inspection, and after the inspection is completed without any problems, it can be packaged and shipped.

This is the whole production process of exhaust catback,and if you have any questions or needs, please feel free to contact us.Thanks!