As a cooling system manufacture,we would like to share the production procedure and help you gain professional knowledge about production.

Step 1:Making the upper and down plate

We will make it as drawing or your sample and stamp your logo in it.

Step 2:Tank

We have 3 different style for your choice:cast(has mold fee,but price is low)/CNC part(no mold fee)/cut-and-weld(no mold fee and price is low,usually used in water radiator).

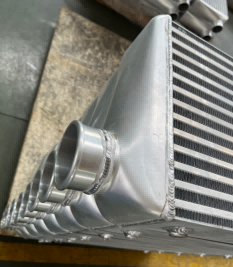

Step 3: Core

A. Fin--Inner fin and out fin

We can make it in different shape,or customize the fin design as your drawing.

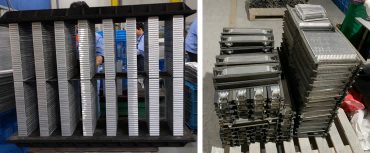

B.Assemble,fix and weld the core

Step 4: Weld the core and tank together,and ensure no leak.

Step 5:Test the pressure and leak for each products.

We ensure each product has 100% fitment and no quality issue when you received it.

Step 6:Coating--in different color

We can make it in black,sliver,green,etc as your requirements.

Step 7: Trimming deformed fins

To ensure the each product has perfect appearance when we pack it.

Step 8: Pack

We will put each product in a carton which has suitable size and full of padding to protect the products during the shipping and save freight.

Using board to reinforce the package and put it on pallet if needed.

Each product will be finished by above steps.

Through these words,hope you get some professional knowledge about radiator production procedure.

By the way,any requirements on customized radiator please feel free to contact us!

My e-mail:sales05@cnjagrow.com