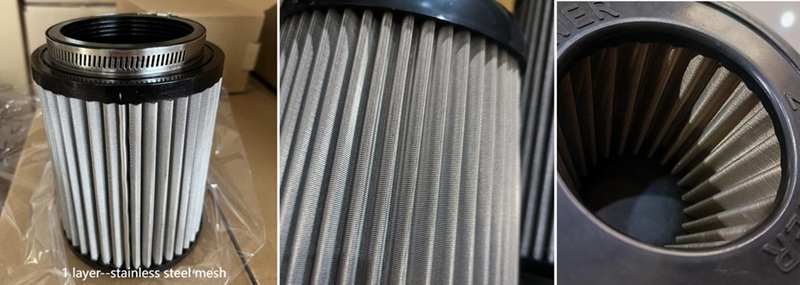

Stainless-Steel Mesh Air Filters – The Upgrade Your Pickup, UTV or ATV Deserves

Whether you’re bombing down a two-track in a RZR, hauling a trailer with your F-150, or crawling rocks in a lifted Wrangler, the air filter is the first—and often last—line of defense between your engine and the dust cloud you’re kicking up. Paper filters clog quickly, oiled-cotton gauze is better but still fragile, and aluminum mesh units are popular on the street. For truly punishing environments, however, stainless-steel mesh is rapidly becoming the go-to choice. Below we break down exactly why.

1. Strength That Laughs at Flying Debris

Aluminum mesh is light and inexpensive, but it dents and deforms when struck by gravel at 80 mph. A stainless mesh filter is typically 2–3× harder on the Brinell scale . Translation: when a rock pings the intake tube on your Raptor, the screen keeps its shape and the airflow stays consistent.

2. Reusable—Not Just “Cleanable”

Both aluminum and stainless filters can be washed, but aluminum threads are softer. After three or four aggressive pressure-washer sessions, the weave can loosen and the screen may sag, letting debris bypass the media. Stainless tolerates repeated ultrasonic baths, degreasers and even a quick shot of brake cleaner without fatigue . In real-world terms, one stainless filter often outlives three aluminum equivalents.

3. Zero Warp in Harsh Heat Cycles

Turbocharged side-by-sides see intake temps spike above 250 °C when the intercooler heat-soaks. Aluminum mesh softens around 300 °C, so a stuck thermostat or a clogged intercooler can push the element past its yield point. Stainless remains dimensionally stable up to 800 °C , ensuring filter-to-airbox seal integrity after every dune run.

4. Corrosion Resistance for Mud and Salt

ATV and UTV riders routinely ford streams coated with magnesium chloride used for dust control. Aluminum mesh oxidizes, the oxide layer flakes, and the openings enlarge. Stainless alloys (typically 304 or 316) shrug off salt, calcium and acidic mud, so the micron rating you bought is the micron rating you keep .

5. Better Flow at the Same Filtration Level

Lab tests show that a 200-micron stainless screen flows ~7 % more CFM than a 200-micron aluminum screen of identical geometry . The reason is wire rigidity: stainless strands can be woven thinner without collapsing under negative pressure, creating a larger open area while still trapping the same particle size. For tuned pickups hunting every last horsepower, that’s free power.

If your weekend involves anything more aggressive than a grocery run, a stainless-steel mesh air filter is the smarter long-term investment. It’s harder, lasts longer, resists heat and corrosion, and flows better than aluminum—all while remaining fully washable. Bolt one in, beat it senseless for 50,000 miles, pressure-wash it, and repeat. Your engine will thank you, and so will your wallet.