Tired of those generic, easily interfered B58 downpipes on the market? We know that precision is the soul of performance modification! Today, we will reveal the rigorous process of developing downpipes for the BMW B58 GEN3 engine, and grandly launch a full range of 4.5-inch, 5-inch, and 5.8-inch pipe diameter products to meet different needs from street advanced to track extremes!

Why is "precision development" so important?

The B58 engine compartment is compact, the original chassis structure is complex, the exhaust pipe route and the gaps with surrounding components (turbine, heat shield, chassis crossbeam, drive shaft, body) are extremely precise. A slight error can lead to installation difficulties and abnormal resonance, or even damage to components and even safety issues. Universal design or simple copying will not work here!

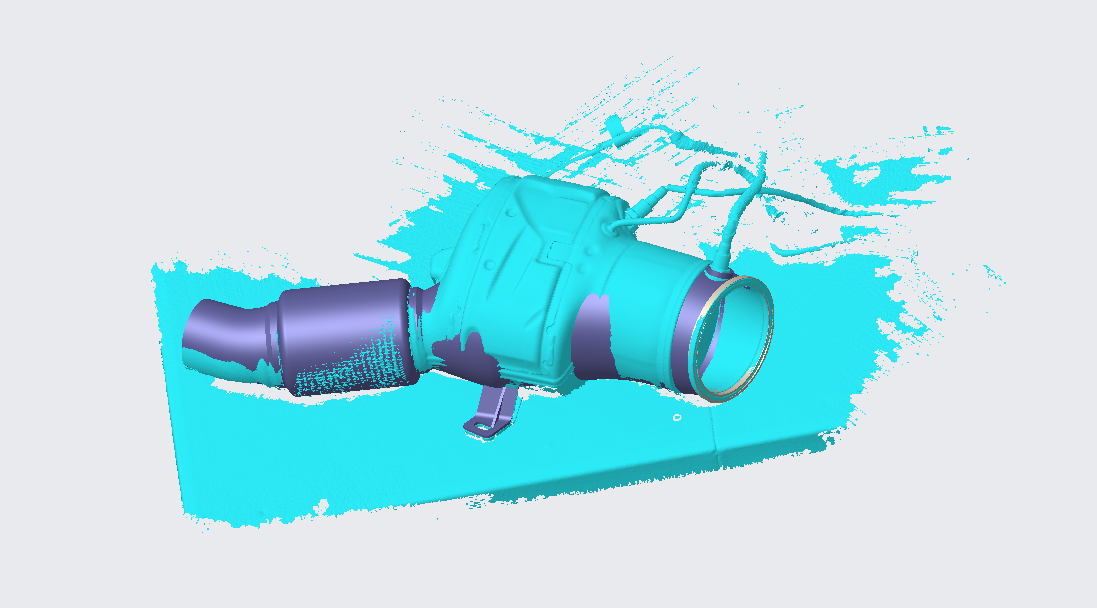

1.Precise starting point: 3D scanning of original chassis data

At the beginning of development, a high-precision 3D scanner was used to perform a full-scale scan of the original chassis and exhaust system of the target model equipped with the B58 GEN3 engine.

Obtain millimeter-level spatial data to accurately restore the turbine outlet position, angle, pipeline direction, and spatial relationship of all potential interference points. This is the cornerstone of all subsequent work, ensuring that the developed head section can perfectly "integrate" into the complex geometric environment of the original vehicle.

2.Digital modeling and optimized design

Based on accurate scan data, our engineers perform 3D modeling in professional CAD software.

Core design considerations:

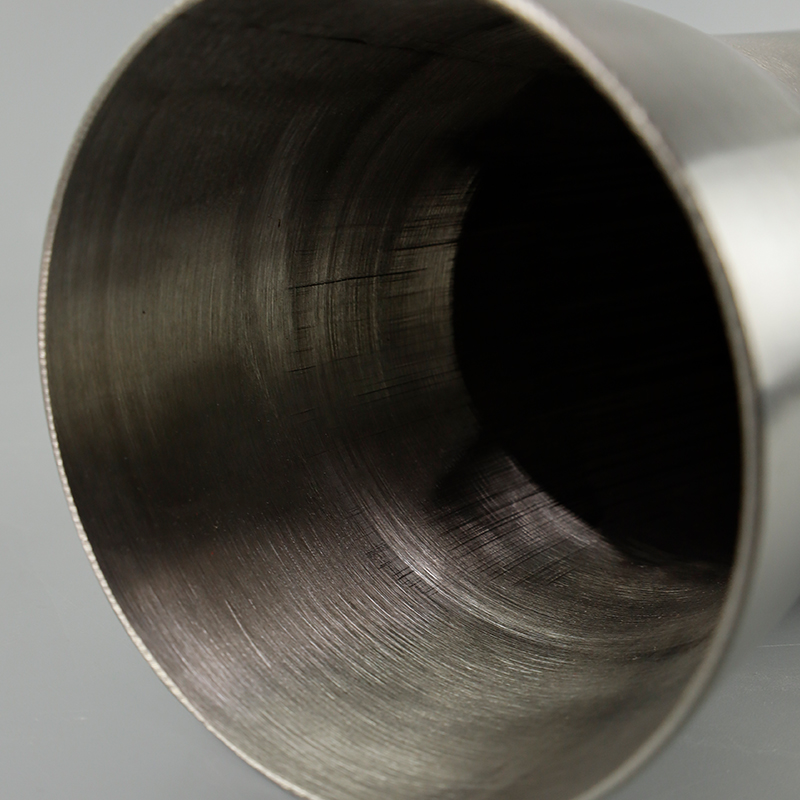

3.Design drawings are just the first step! We 3D print key parts (especially the complex turbine outlet flange interface and elbow transition area) to create a 1:1 physical model.

This model will be placed on the actual vehicle for "pre-installation" verification. Engineers will carefully check:

4.Precision jigs - guarantee of mass production consistency

After 3D printing model verification and design optimization, we enter the jig & fixture production stage. With the jig, Experienced welders use fixtures to efficiently and accurately complete the welding of each product, ensuring that each product can be perfectly installed on the GEN3 vehicle.

Please feel free to contact me if you are interested in this new developed downpipe!